Quick update! I had some hobby paint at home and since I already did file down the wood earlier after the sawing and I had the time – I went for it. Possibly the easiest step so far, painting the arms. I like to work with wood as a material. Much more pleasant than aluminum. Hey look another use of my Dremel workstation! Yey!

Prototype done!

So here is the final prototype for my motormount.

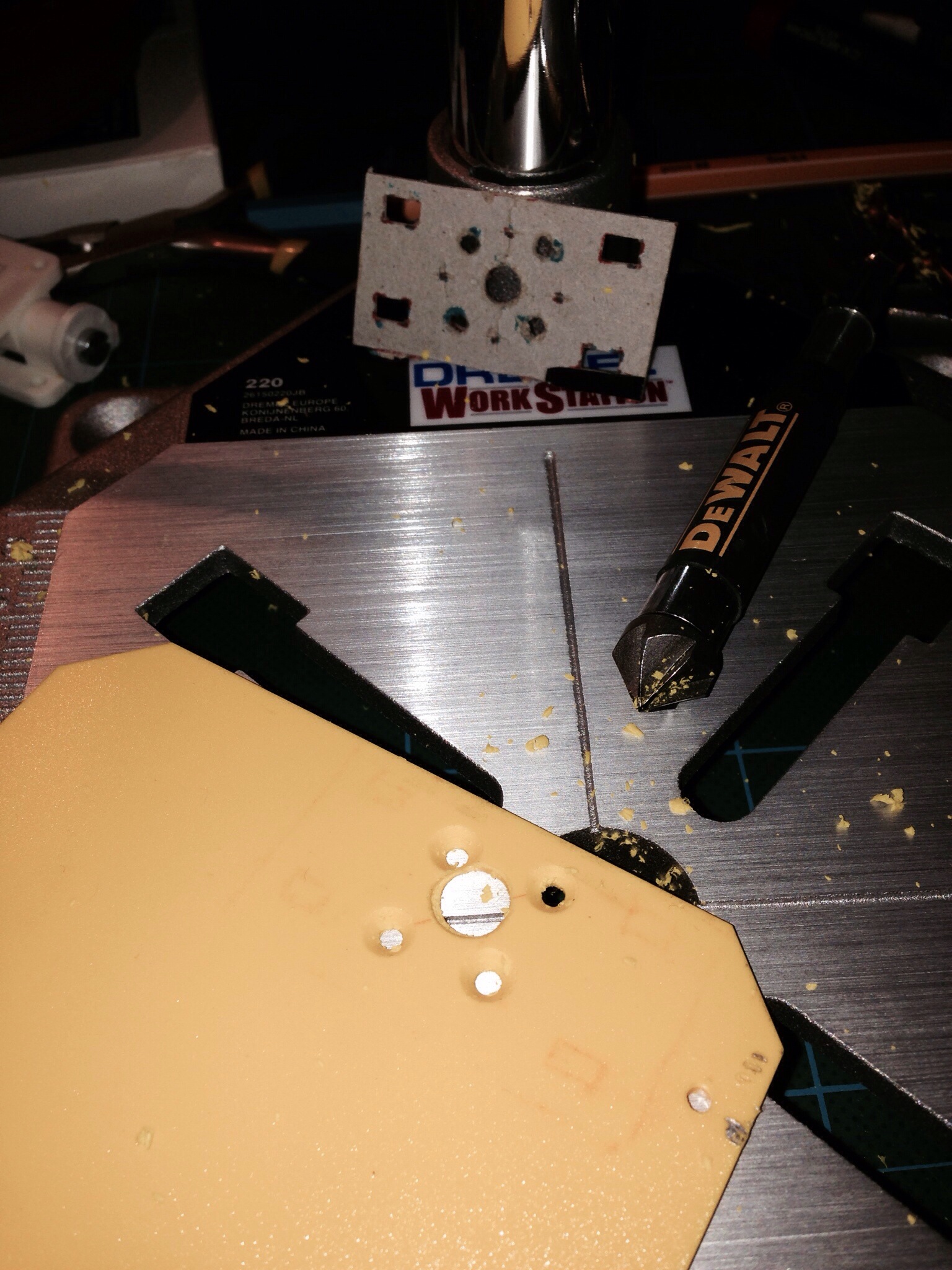

I might have used the wrong bit for the Dremel. I used a carving bit for engraving but should have tried the cutting bit first. Now I had to do layer by layer like 20passes for each cut. Maybe I don’t need to do that if the cutting bit works with this plastic… I’ll try that next time.

Drilling in plastic…

So i felt the need to own a Dremel. Bought one. Started to create a first prototype in plastic. I’m pretty sure I need another material for the real thing though. I googled polystyrene and it’s melting point is 240-260 ‘c. I used my multimeter with the temp-sensor to measure the temp of the tip of my soldering iron. Got about 70-110. Tried to apply some of that heat for a couple of seconds. It melted. And it also melted some during drilling. Making a mess out of my drill. So maybe it’s not polystyrene plastic or my reasoning is flaud. I will look for another material with better heat resistance. How about some kind of metal perhaps?