So I have an idea on how to build some motormounts for the AX2810Q (16x19mm cross) to attach with zipties to my wooden booms. I also found other examples on people executing that idea. But using materials and methods of manufacturing that I don’t have access to. I will however try out this thing anyway. By prototyping my way forward from what I began with and created this evening, in cardboard. Needless to say, I will use a somewhat more rigid material in the finished product ;-). Here’s a pic on what this process looks like right now.

Bearings upgrade

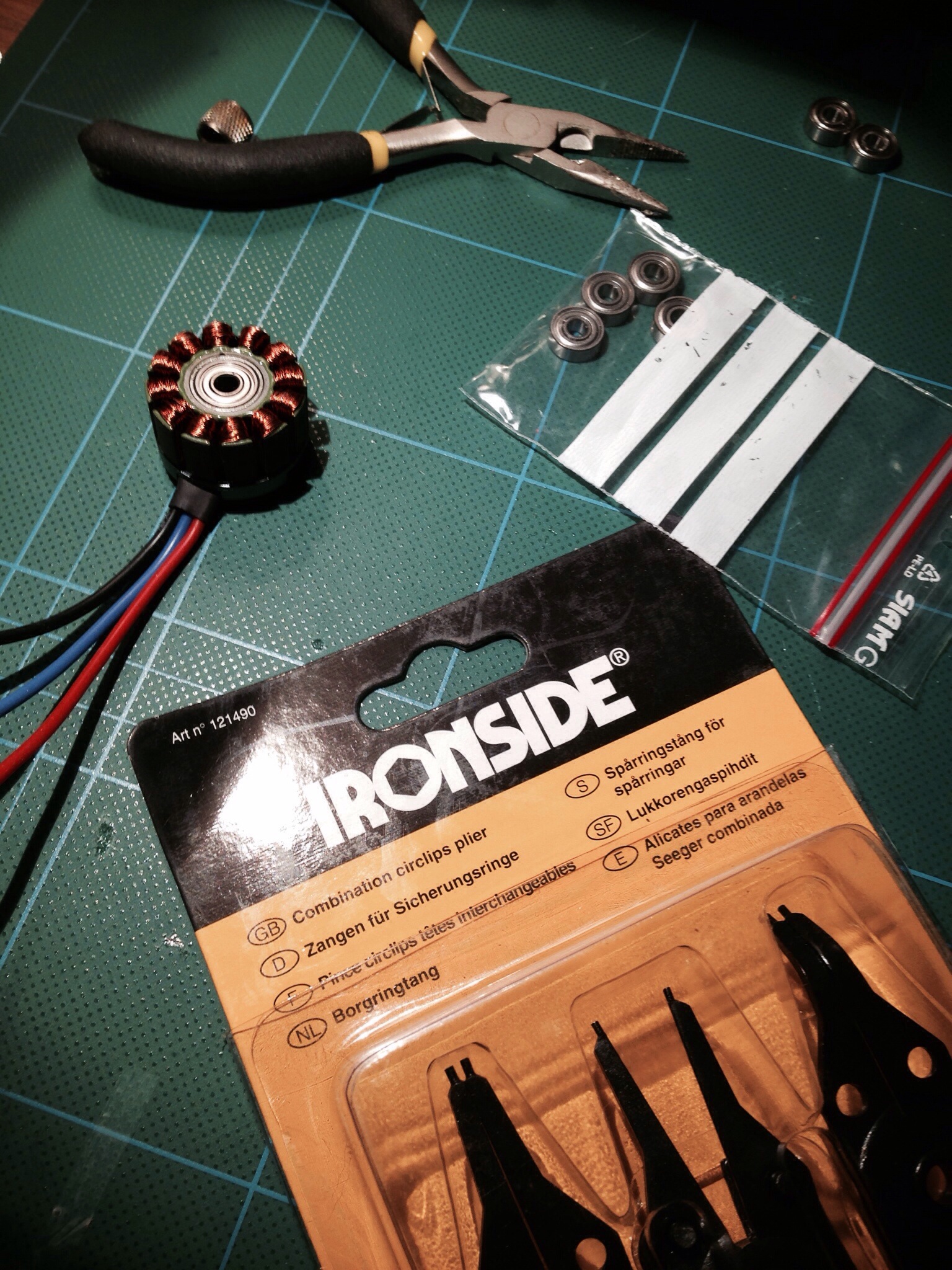

I also bought the kind of pliers needed to disassemble the motors today… hmm…).

Unfortunately I was only successful in replacing the two bearings of one motor. The others where totally stuck and so wouldn’t budge. I gave up. Thinking a broken motor is worse than a bad- or “prone to break and get bad”-motor. I also found something weird stuck in the casing around the magnets… Possibly something that should be left there, maybe for balancing? Some brown/black solidified paste or sediment. I didn’t feel like scraping that off. What if I break the balance? I also found out that there’s abit of oxidation, as you can see in pictures below.

But I’m not sure that’s a problem either. Perhaps it’ll burn off or something when I run the motors hot (which I shouldn’t do)…

Motor-tilt-hinge

I almost forgot that I think I managed to assemble a working hinge for the tilt mechanism yesterday night. Not as pretty as David’s carbon fiber axeled but I had a screw that fitted nicely. Locally available parts precede fancy materials if they are good enough. 🙂 Here it is!