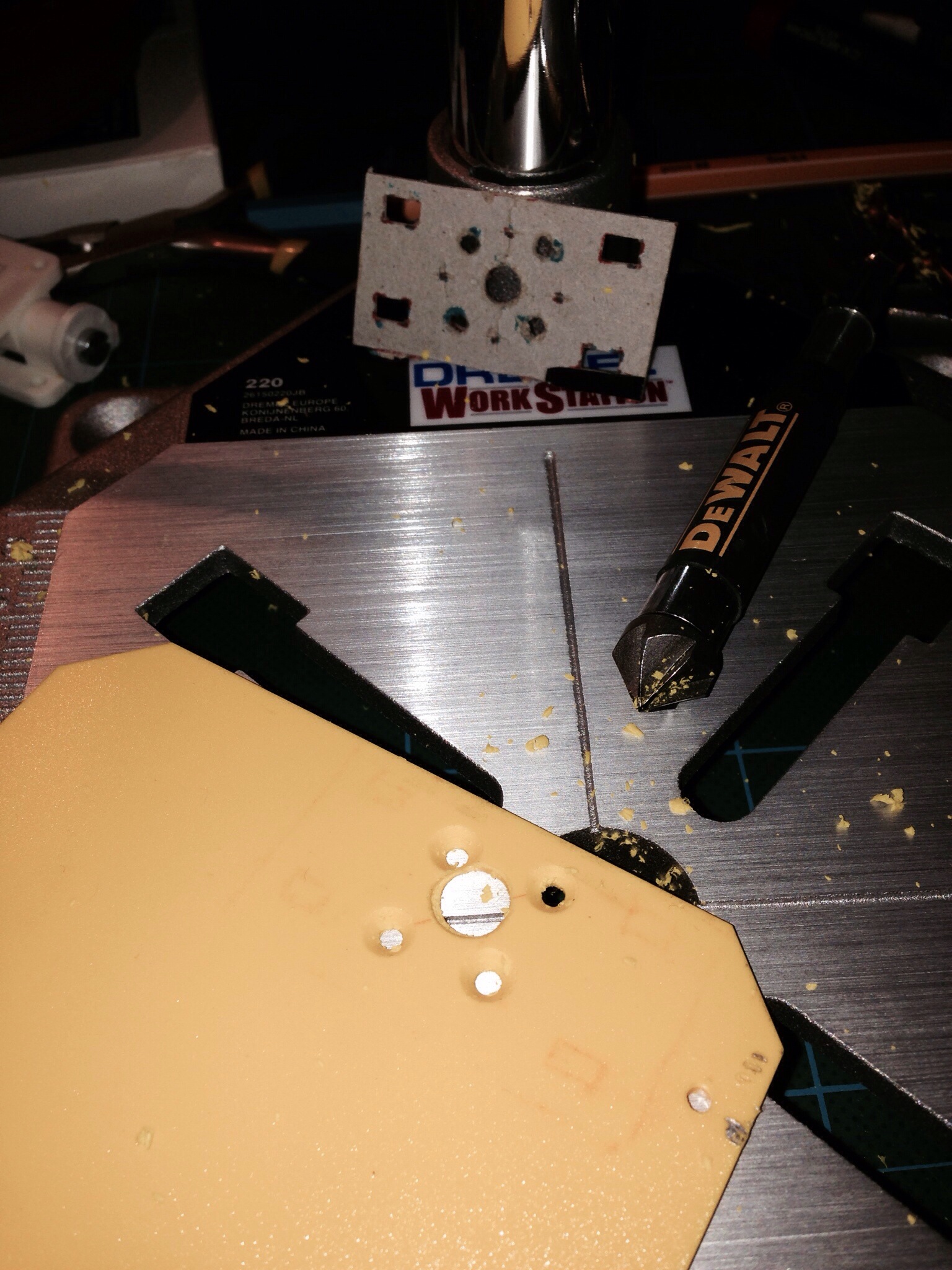

So I finally got to sawing the sticks into arms. With my dremel the once forseen problem with using 14x14mm sticks instead of 12.8×12.8mm soon vanished. As you can see in the images below I carved it down on one side and it is a perfect fit, somewhere around 13x14mm. I also drilled the holes using the Dremel with workstation. I managed to put the two in the back arm in pretty much perfect center and aligned with the bat bone (not done yet in the picture). It seemed impossible at first, especially since I had moved my support bits that held the wood in place. Managed to align and with careful testing and tiny corrections I got it. I’m not even sure if I can replicate that ever again. So I hope they never break…

So here is the first picture of how large it will become once built. Even though there’s still much to do this milestone felt so good. 🙂

Yey! It can has propellers! Lolz!

My cat felt I needed her in the picture for size comparison. She is quite a sturdy cat though 😉

My cat felt I needed her in the picture for size comparison. She is quite a sturdy cat though 😉